Cobra Crane & Hoist delivers sanitary-grade crane systems designed to support food-safe operations while maximizing uptime and product flow. We specialize in crane solutions that are easy to clean, resistant to corrosion, and built to perform under washdown and high-humidity conditions common in food and beverage processing environments.

Food and beverage processing facilities operate under strict sanitary requirements and regulatory oversight. Every piece of equipment must be designed for easy cleaning, prevent contamination, and maintain food safety standards throughout production processes.

Crane systems in food environments face unique challenges including frequent washdowns, temperature extremes, corrosive cleaning chemicals, and stringent hygiene requirements. The right crane solution supports production efficiency while meeting all food safety regulations and industry standards.

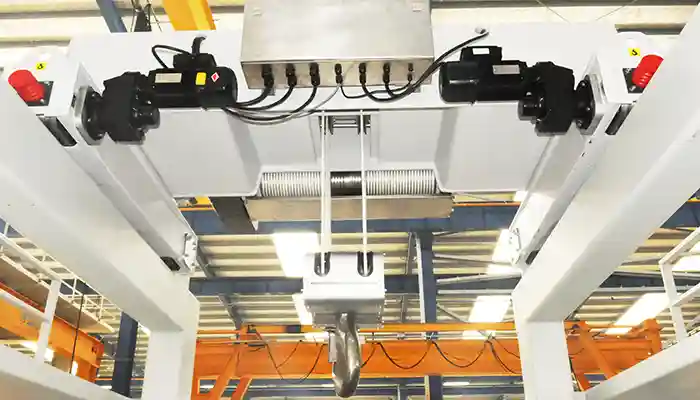

Crane systems built with stainless steel components and food-grade materials. These systems resist corrosion, provide easy cleaning surfaces, and maintain sanitary conditions required in food processing environments.

Crane systems designed for cold storage, freezer operations, and high-temperature processing environments. Specialized construction maintains performance across extreme temperature ranges.

Crane systems designed for cold storage, freezer operations, and high-temperature processing environments. Specialized construction maintains performance across extreme temperature ranges.

Enclosed track systems and sealed components that prevent lubricant dripping and foreign material contamination. Designed to maintain product integrity throughout processing operations.

Crane designs that facilitate cleaning and maintenance while minimizing production downtime. Quick-access components and simplified maintenance procedures support operational efficiency.

Wondering if a Food-Crane System is the right fit for your facility? Contact our experts today for personalized guidance and a tailored crane solution.

Our food and beverage experience includes understanding regulatory requirements, sanitary design principles, and operational demands of food processing facilities. We design crane systems that support both production efficiency and food safety compliance.

All crane systems designed to meet FDA, USDA, and other applicable food safety regulations.

Expertise in food-grade materials, washdown procedures, and contamination prevention strategies.

Proven track record supporting bakeries, beverage operations, meat processing, dairy facilities, and other food operations.

Specialized maintenance programs that maintain food safety standards while maximizing equipment uptime.

Our crane systems meet all applicable food safety regulations including FDA guidelines, USDA requirements, and SQF standards.

All materials and components are food-grade approved and suitable for direct and indirect food contact applications.

Crane designs follow sanitary design principles with smooth surfaces, minimal crevices, and accessible cleaning points.

Complete documentation packages including material certifications, cleaning procedures, and maintenance protocols.

Assistance with system validation, HACCP integration, and regulatory compliance verification.

From ingredient handling to finished product packaging, Cobra Crane & Hoist delivers crane solutions that maintain food safety while improving operational efficiency.

Contact our food industry specialists for your sanitary crane solution.